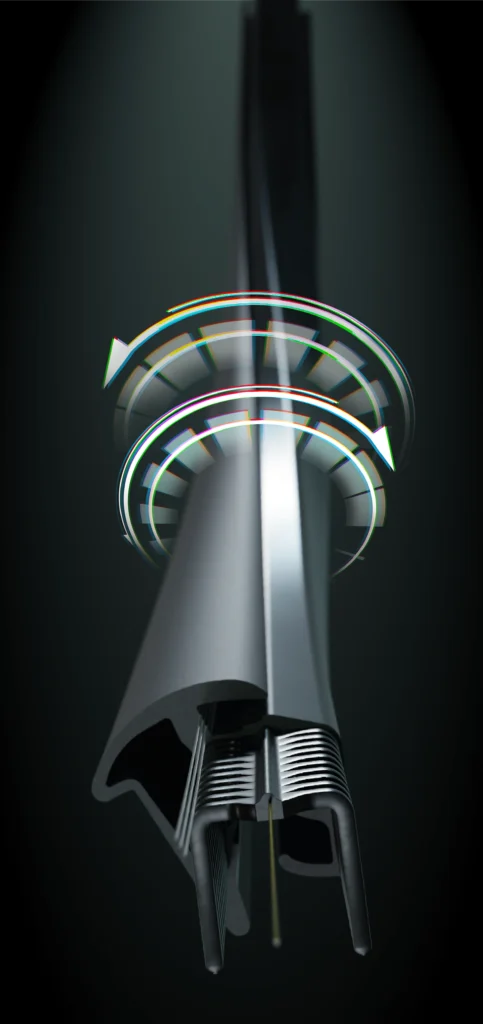

In the world of automotive sealing, precision is everything. The shape and performance of a body seal influence not only the tightness and acoustic comfort of a vehicle, but also the entire assembly and manufacturing process.

That’s why at Draftex, we emphasize a fundamental truth:

💡 The earlier we’re involved, the better your seal will be – and the lower your future costs.

With nearly 70 years of experience in designing and producing body seals, we’ve seen it all: changes made too late, last-minute design fixes, and costly reworks in full production. Each adjustment after the tool design or SOP stage results in delays, scrap, or even a complete remanufacturing of dies and prototypes – all of which could have been avoided.

Draftex design department was established in early 60’s

Designing for Perfection

Our engineering teams work closely with our customers from the very first concept sketches. By selecting the right shape and materials early on, we help avoid geometries that may lead to leakage, deformation, or mounting issues.

Regardless of whether you are designing a dynamic or static seal, its shape, material properties and resistance are crucial to the success of the project.

The Power of Simulation and Testing

Before the first prototype is extruded, our engineering team works closely with customers in advanced simulation environments. These test scenarios mimic real-world mounting and performance conditions, allowing us to predict and optimize sealing behavior without producing a single physical part. This not only saves time and money, but also supports more sustainable development.

Experience You Can Trust

We’ve been part of this industry since 1958. Our seals are fitted in ultra-luxury vehicles, global platforms, and specialty applications. The key to our success? Deep know-how, close collaboration, and the ability to anticipate challenges before they happen.